What do you get when you mix a large clumsy geek, a dark house, and a poor defenseless baby safety gate? An excuse to make parts of course! While blundering around in the dark I managed to shear off the hinges on the baby gate that guards the top of our stairs. I have repaired them a time or two but they were never quite the same and finally there wasn’t enough material left to repair. With time off work and some shiny new 1″ thick HDPE for Christmas I decided to make some new brackets. The design was done in Google Sketchup and exported as DXF. Vectric Cut2D took in that geometry and I created the tool paths. After an air cut to see what kind of mood the CNC was in (it has been idle for months) I let the chips fly. The posts the gate attach to were fabricated from a couple of sacrificial 5/16″ nylon bolts. In hindsight I should have left some thread on and topped it off with a flange nut. Should the gate decide it likes to pop off enough I’ll upgrade the posts.

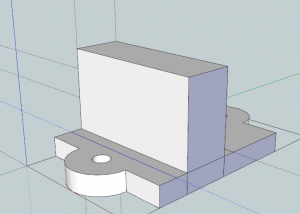

Sketchup model

Repaired gate

Bracket detail

Here are some rough, unedited videos. Note that the router is very loud so you will most likely need to crank down your audio.

The air cut, some closeups of the CNC machine

Cutting the first bracket.